The last business is to press out the multiplier and the package of control chamber. Accurately we press the pivot from the bottom with something not hard but blunt-pointed in order not to harm. Using the wood stick (as example) we press out these ones out of the injector’s package.

On the package of the control chamber (on the left on the picture above) approximately in the middle there are two intermediate layers and at the end of the article you can see their code. It is not difficult to change these ones — I read that these layers are disposable. But if you have not such opportunity to change these ones there would be better not to touch its as far as it is possible to harm layers and these ones will not functional.

The code of multiplier is in the end of the article.

Here the details which you can recognize and mentioned in theory. But I cannot show the control chamber by sections.

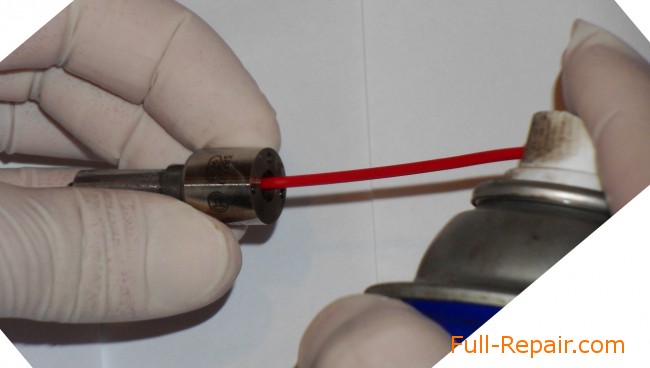

Now the injector is taken to pieces and there is time to clean all its components. For this purpose I applied duster, carburetor cleaner and solvent. Nozzle was blown with the help of cleaner’s balloon.

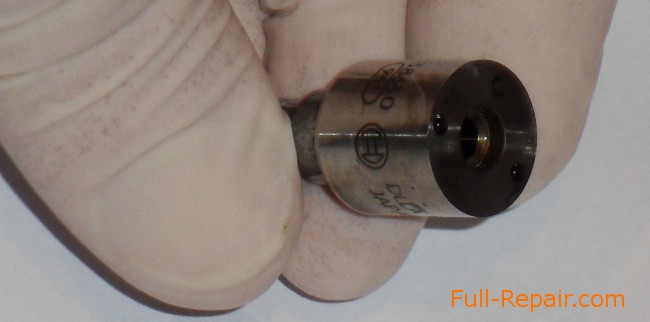

There were 6 faculas in the output to the different directions. I rubbed needle with the duster moistened with the carburetor cleaner and ideally the needle must be shined without any yellowcolours. The next important detail of injector is back valve. The ball and its housing may be dirty.

Full-Repair.com

Full-Repair.com

Comments:

24.04.2014 at 23:11 Samuel said:

You are a great man! Marvelous!

I never have seen more detailed report!

I spend all my afternoon to read your reports. And they are exelent.

Thank you very much for the good information and the good time I passed with!

13.12.2014 at 23:05 Mr. Magiroos said:

Perfect!!!! Super!!! This is just for my kind men. I just have to do things my self. One question.

Is there any rubber seals to change? Can you send me the factory code to order them. My problem starts from leaking upper line. I have chrysler voyager 2,4 crd. 2002 diisel. Many thanks!!!

14.10.2016 at 02:16 Scottie said:

Thank you for the detailed write up. Diesel injector rebuilding seems to be a dark art, with very little published on the internet. Your article is the most comprehensive I've seen. I purchased my valve balls from VXB.com

Kit13315 1.3mm Loose Ceramic Balls G5 Si3N4 Bearing Balls $1.49 each

14.10.2016 at 11:03 George said:

Dear Scottie,

Thanks! Yes, it's some kind of dark art. Did you successful repair your injectors? As I know ball diameter is 1.34mm.

10.10.2017 at 03:10 Axallindo said:

Hi guest

I have clean all injector part and change a new seal and new nozzle but why after i use at my engine is always knocking in acceleration?

10.10.2017 at 03:10 Axallindo said:

Hi guest

I have clean all injector part and change a new seal and new nozzle but why after i use at my engine is always knocking in acceleration?

19.07.2018 at 21:15 Henry said:

Hi,

Need your permission to translate this article in bahasa indonesia and upload it to my blog.

Regards,

Henry

24.07.2018 at 19:28 George said:

Dear Henry,

I do not mind if you will translete the article and upload to your blog with link to the source.

REgards, George.

16.07.2019 at 16:34 Zox said:

Hi,

Like Axallindo, I have cleaned injectors and put new seal and ball. Now I have knocking injectors on acceleration...

It looks like that injector must be adjusted with shims and take care about torque settings.

Pre-ignition paremeter is not good...